SPIREX thermal transfer tubes make saving energy easy.

The GP1000 Series can heat or cool as your purpose requires.

Whether you want to save and recover the heat lost down your domestic shower drain or cool your industrial product such as milk or wine, SPIREX provides the thermal transfer solution for your home, business or industry.

SPIREX - helically corrugated thermal transfer tube.

Available standard in copper, stainless steel, titanium - (aluminium special).

Double wall (vented) shown below - a copper tube formed onto a titanium tube creating a double wall protection.

The GP SERIES applications of the SPIREX tube include:

- Pneumatic to Liquid

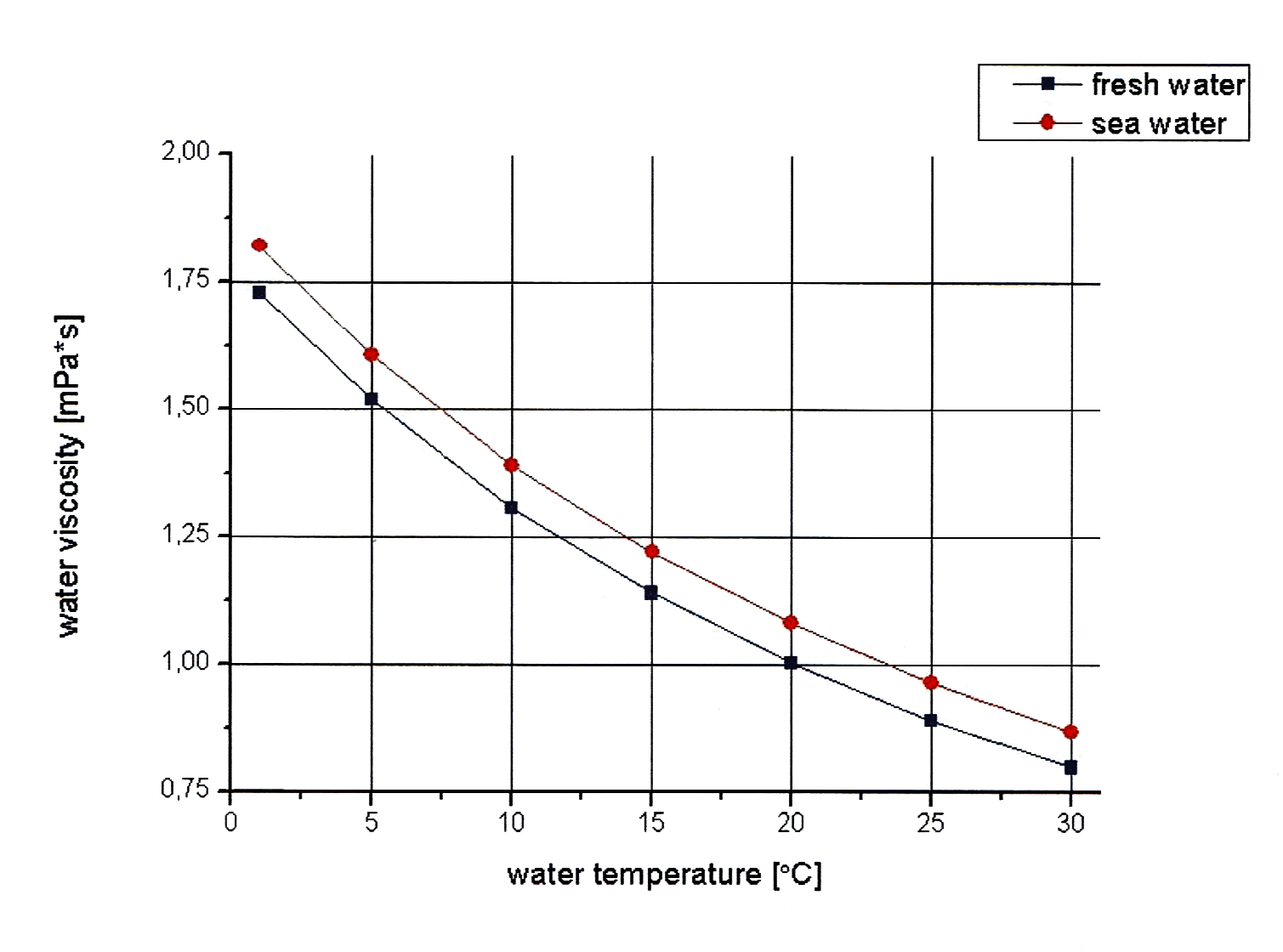

- Marine Engine Oil to Seawater

- Seawater to Freshwater

- Liquid to Liquid

- Seawater to Seawater

- Solar Heated Liquid to Potable Water

- Refrigerant to Liquid

- Freshwater to Freshwater

- Solar Heated Liquid to Swimming Pool Water

- Hydraulic Oil to Water

- Geothermal Liquid to Water

The dynamic helical form of the SPIREX tube offers new and effective alternatives in:

- Heating

- Cooling

- Expansion

- Vibration

- Emission Control

- Noise Suppression

- Dryers and Aerators

- Tubes Heat Exchange

- Mixing and Separating

- Double Wall

- Vented

- Decorative

Sectors that can benefit from SPIREX:

- domestic shower

- dairy industry

- swimming pools & spas

- aquariums

- gymnasium

- hotel

- schools

- solar (hot water)

- salt water

- hydroponics

- chemical processing

- aquaculture

- wine & juice making

- beer brewing

- processing (food)

- hazardous waste

- hydraulics

- pneumatics (air/gas)

Grade 1 Titanium or 316 Stainless Steel

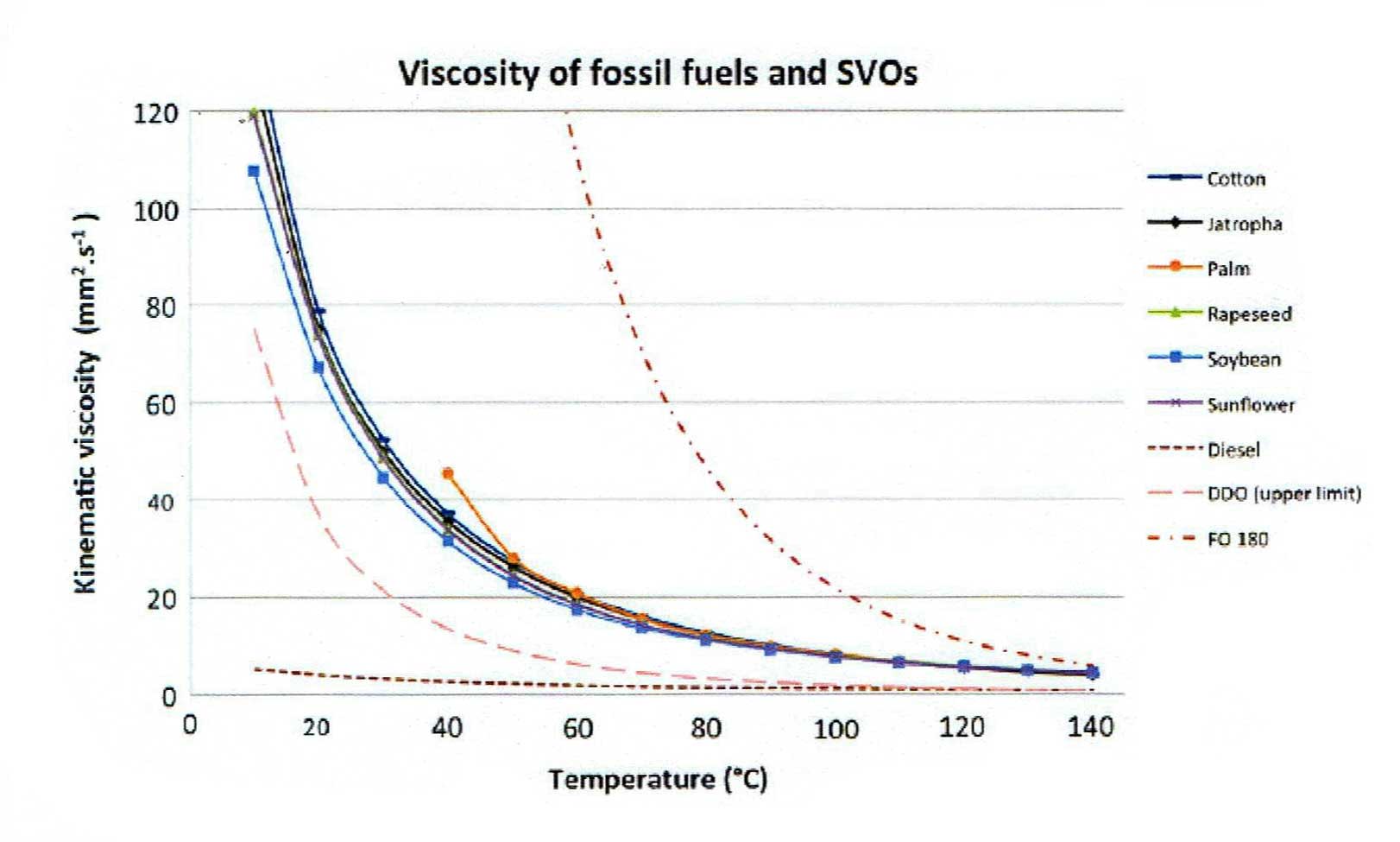

Temperature range up to 120°C at 200Psi

Chemical resistant • Cleanable • Compact and light

Nylon II

Temperature range up to 110°C at 200Psi

Chemical resistant • Cleanable • Compact and light

Grade 1 Titanium or 316 Stainless Steel

Temperature range up to 98°C at 150Psi

Chemical resistant • Cleanable • Compact and light

Polyethylene

Temperature range up to 30°C at 50Psi

Chemical resistant • Cleanable • Compact and light

316 Stainless Steel

Temperature range up to 350°C at 900Psi

Chemical resistant • Cleanable • Compact and light

316 Stainless Steel

Temperature range up to 350°C at 250Psi

Chemical resistant • Compact and light

Grade 1 Titanium or 316 Stainless Steel

Temperature range up to 120°C at 250Psi

Chemical resistant • Cleanable • Compact and light

316 Stainless Steel (dismantles for cleaning)

Temperature range up to 150°C at 200Psi

Chemical resistant • Cleanable • Compact and light

Copper

Temperature range up to 320°C at 900Psi

Cleanable • Compact and light

vented)

Copper

Temperature range up to 320°C at 900Psi

Compact and light

Grade 1 Titanium or 316 Stainless Steel or Copper

Temperature range up to 120°C at 900Psi

Chemical resistant • Compact and light

(vented)

Copper

Temperature range up to 320°C at 900Psi

Compact and light

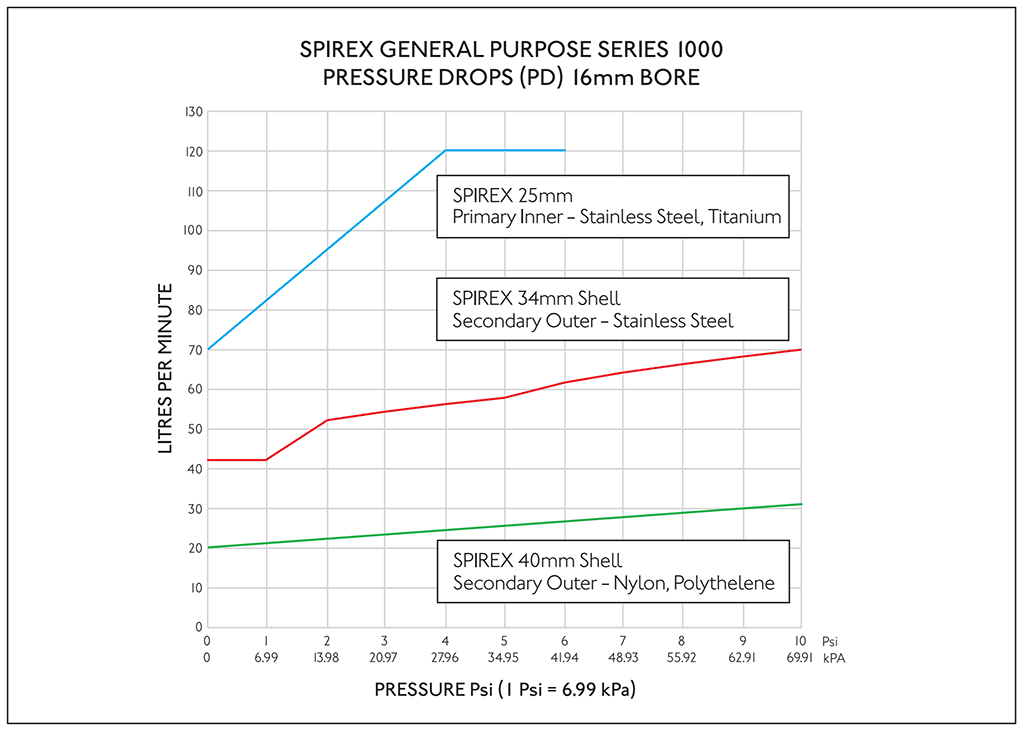

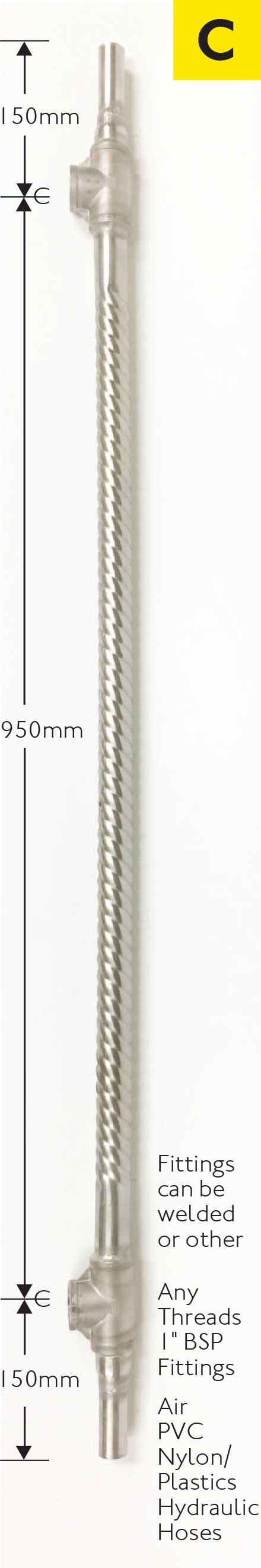

- Grade 1 Titanium or 316 Stainless Steel

- Temperature range up to 120°C at 200Psi

- Chemical resistant inner tube

- Cleanable

- Compact and light

- Nylon II (dismantles for cleaning)

- Temperature range up to 110°C at 200Psi

- Chemical resistant shell

- Cleanable

- Compact and light

- aquaculture

- beer brewing

- wine & juice making

- swimming pools & spas

- processing (food)

- hydroponics

- dairy industry

- salt water

- solar hot water

- hydraulics

- pneumatics (air/gas)

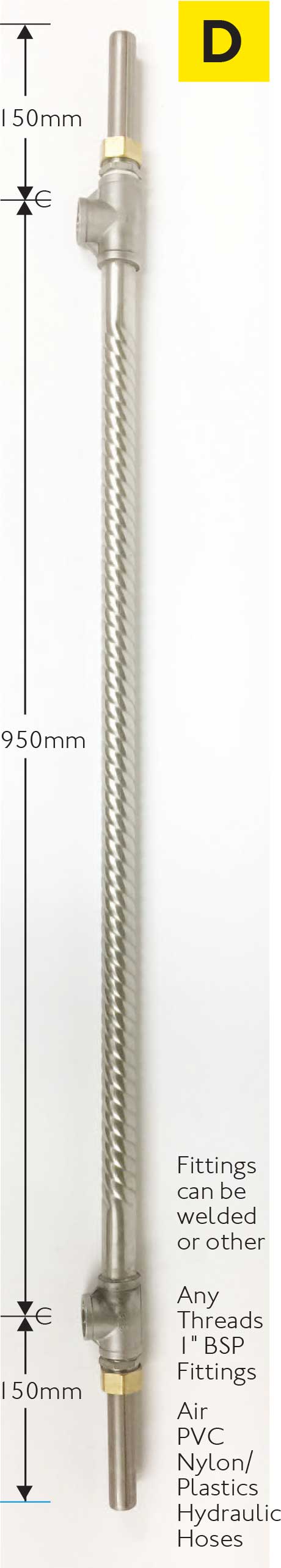

- Grade 1 Titanium or 316 Stainless Steel

- Temperature range up to 98°C at 150Psi

- Chemical resistant inner tube

- Cleanable

- Compact and light

- Polyethylene (dismantles for cleaning)

- Temperature range up to 30°C at 50Psi

- Chemical resistant shell

- Cleanable

- Compact and light

- aquaculture

- beer brewing

- wine & juice making

- swimming pools & spas

- processing (food)

- hydroponics

- dairy industry

- salt water

- solar hot water

- hydraulics

- pneumatics (air/gas)

- 316 Stainless Steel

- Temperature range up to 350°C at 900Psi

- Chemical resistant inner tube (check chemical compatibility)

- Cleanable

- Compact and light

- 316 Stainless Steel

- Temperature range up to 350°C at 900Psi

- Chemical resistant shell (check chemical compatibility)

- Compact and light

- aquaculture

- beer brewing

- wine & juice making

- processing (food)

- hydroponics

- dairy industry

- solar hot water

- hydraulics

- pneumatics (air/gas)

- oils

- glycols

- saturated steam

- 316 Stainless Steel or Grade I Titanium

- Temperature range up to 120°C at 250Psi

- Chemical resistant inner tube

- Cleanable

- Compact and light

- 316 Stainless Steel (dismantles for cleaning)

- Temperature range up to 150°C at 200Psi

- Chemical resistant shell

- Cleanable

- Compact and light

- aquaculture

- beer brewing

- wine & juice making

- swimming pools & spas

- processing (food)

- hydroponics

- dairy industry

- salt water

- solar hot water

- hydraulics

- pneumatics (air/gas)

- oils

- glycols

- Copper

- Temperature range up to 320°C at 900Psi

- Cleanable

- Compact and light

- Copper

- Temperature range up to 320°C at 900Psi

- Compact and light

- refrigeration use

- beer brewing

- wine & juice making

- hydroponics

- dairy industry

- heat/cool fresh water

- solar hot water

- hydraulics

- pneumatics (air/gas)

- oils

- glycols

- evaporators

- condensers

- 7.5kW@2.2°C Diff@50L/m

- 4.7kW@1.7°C Diff@40L/m

Note 1: Condenser applications where rejected heat goes to waste, insulation is not required and increased heat rejection is achieved from the outer shell depending upon ambient temperature.

Note 2: Specifications are subject to change without notice due to the manufacturers ongoing research and development programme.

- Copper or Titanium or Stainless Steel 316

- Temperature range up to 120°C at 900Psi

- Chemical resistant Titanium

- Compact and light

- Cleanable

- Copper

- Temperature range up to 320°C at 900Psi

- Compact and light

- aquaculture

- beer brewing

- wine & juice making

- swimming pools & spas

- processing (food)

- hydroponics

- dairy industry

- salt water

- solar hot water

- hydraulics

- pneumatics (air/gas)

- oils

- glycols

- refrigeration

- evaporators

- condensers

- 5.0kW@1.2°C Diff@60L/m

- 2.5kW@1.1°C Diff@33.3L/m

Note 1: Condenser applications where rejected heat goes to waste, insulation is not required and increased heat rejection is achieved from the outer shell depending upon ambient temperature.

Note 2: Specifications are subject to change without notice due to the manufacturers ongoing research and development programme.

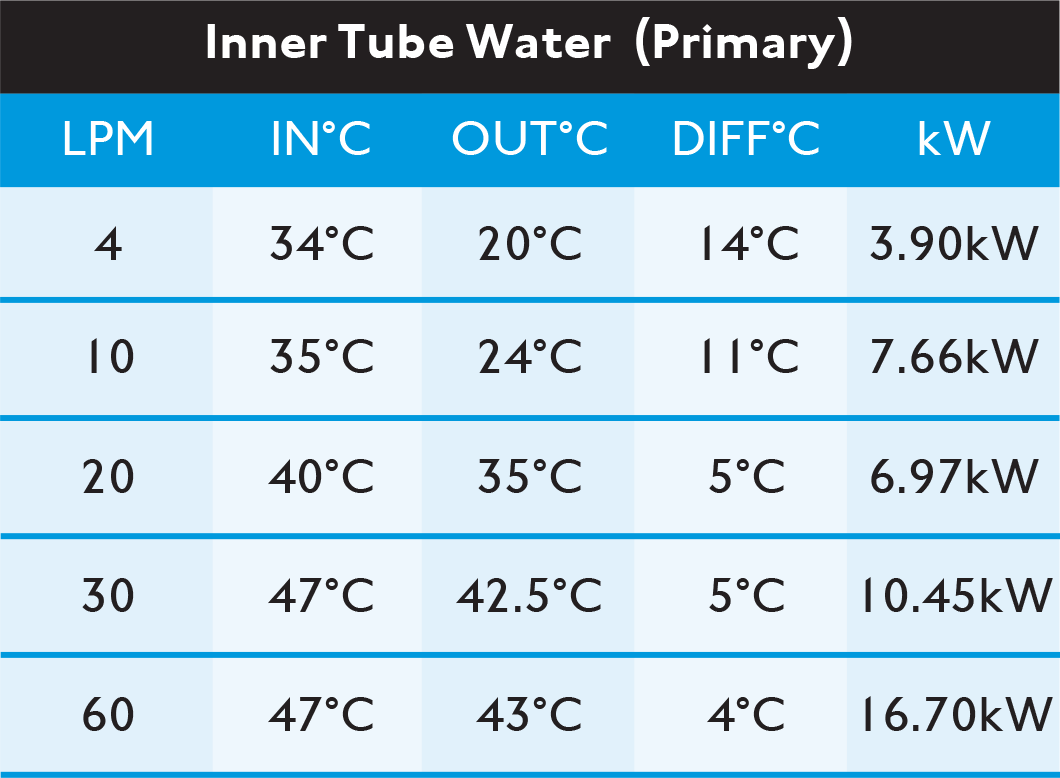

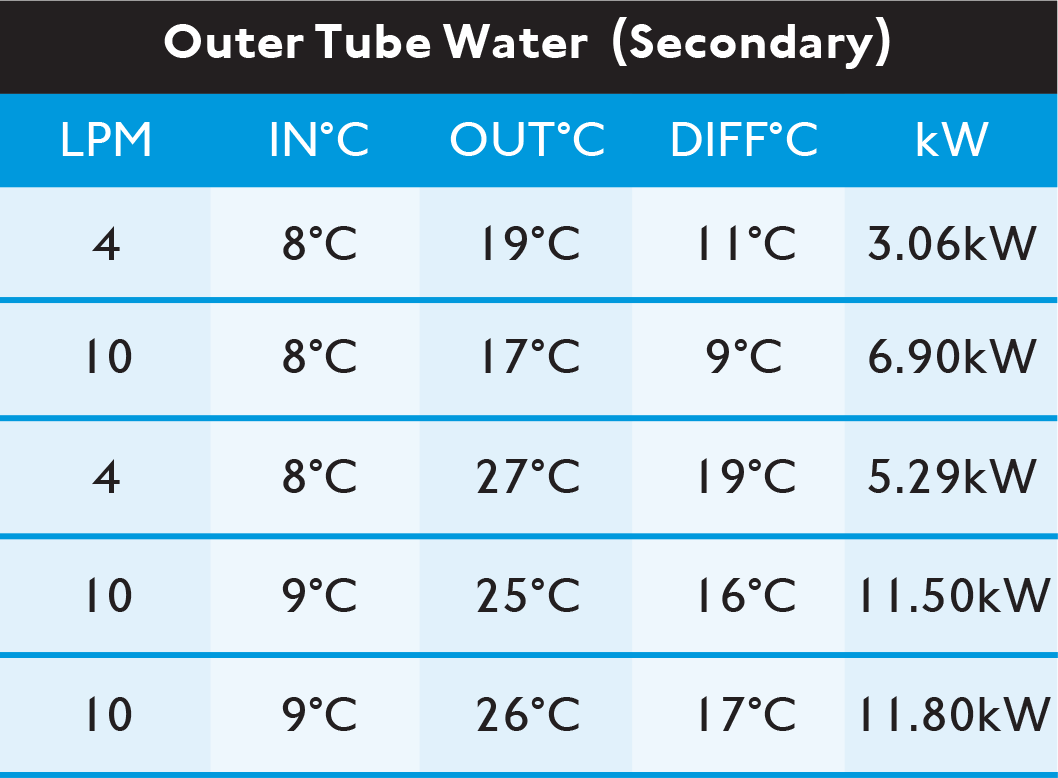

Note 1: Heat exchanges should be mounted vertically or slightly angled up with inlet and outlet fittings upwards to prevent airlocking. If possible, counter flow with primary flowing up (flooding), secondary low flow is recommended the same way to stop airlock for best performance.

Note 2: Results show higher flows provide improved performance.